High value compounds that microalgae can produce increased the need for better harvesting techniques. Valuable Products from Algae Using New Magnetic Cultivation and Extraction Techniques (Acronym: VALUEMAG) is a BBI-JU/Horizon 2020 project that started on April 2017 and aims to develop new microalgae cultivation methods which, among other things, may enhance harvesting processes (https://www.valuemag.eu/).

It was put forward and is currently carried out by an international consortium of European Universities and companies coordinated by the National Technical University of Athens, with Università degli Studi della Campania “L.Vanvitelli” and ENEA (Italian National Agency for New Technologies, Energy and Sustainable Economic Development) as Italian partners.

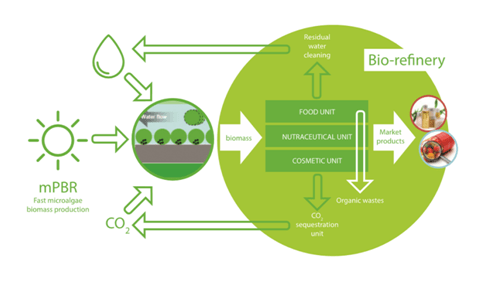

VALUEMAG aims at investigating cutting-edge solutions for microalgae production and harvesting as well as scaling up biomass transformation systems in order to work out new technologies for aquatic/marine biomass integrated bio-refineries.

Production-cultivation and harvesting objectives are achieved using magnetic nanotechnologies: superparamagnetic iron oxide nanoparticles (SPAN) are introduced into microalgae protoplasm in order to confer them magnetic properties. Magnetic microalgae growth is carried out in a magnetic Photo-BioReactor (mPBR) in which cells are immobilized onto a soft magnetic conical surface and covered with a thin layer of circulating water. A greenhouse hosts the mPBR system to expose microalgae to light, minimize contamination and temperature-humidity uncertainties. Quantity of water is minimized and harvesting will be fast and inexpensive. These innovations permit optimum cultivation, enhance biomass productivity and dramatically lower costs of biomass production. Biomass is directly utilized by VALUEMAG multi-facilities bio-refinery for the production of molecules for pharmaceutical, nutraceuticals, food additives, natural anti-microbial (figure below) and cosmetics. Using selected microalgae strains, natural products will be extracted by using supercritical CO2, while a new selective magnetic separation method for precise selection of high-value products will be also developed. To further reduce the amount of greenhouse gases and biomass costs, the CO2 from the transformation processes and water are recycled and used to enhance the microalgae growth rate. The project outputs will bring a broad range of valuable products onto the market in sustainable way. In particular, the VALUEMAG chain will allow for the exploitation of the full potential of aquatic biomass. Finally, the competitiveness of the European industry will be improved since at present there is no pilot installation or state-of-the-art bio-refinery utilizing magnetic nanotechnology to cultivate microalgae.

VALUEMAG project has received funding from the Bio Based Industries Joint Undertaking and the European Union’s Horizon 2020 research and innovation under the grant agreement No. 745695